What is the Supply Chain ?

The Supply Chain: an essential process in our society.

“Supply Chains are in competition,

not companies” Martin Christopher.

At the heart of our activity, the supply chain is an essential process in order for our society and our consumption to function well. It is an international network, used to deliver goods and services to consumers. From raw materials to final products in the client’s hands, it constitutes a chain of process and actors that are synchronized.

In recent decades our economy’s globalization has led to a strong multiplication and increase of exchanges. The continuous improvement of our technologies always enables faster delivery time, which creates the need of logistics and supply chains more and more efficient and competitive. If we take two companies that sell the same product, the one with the most efficient supply chain and which guarantees the fastest and most qualitative delivery will always be the one that the client will opt for.

The supply chain’s challenge is to make products accessible at the right time, the right place and especially at the right price. The fulfilment of the customer promise is crucial.

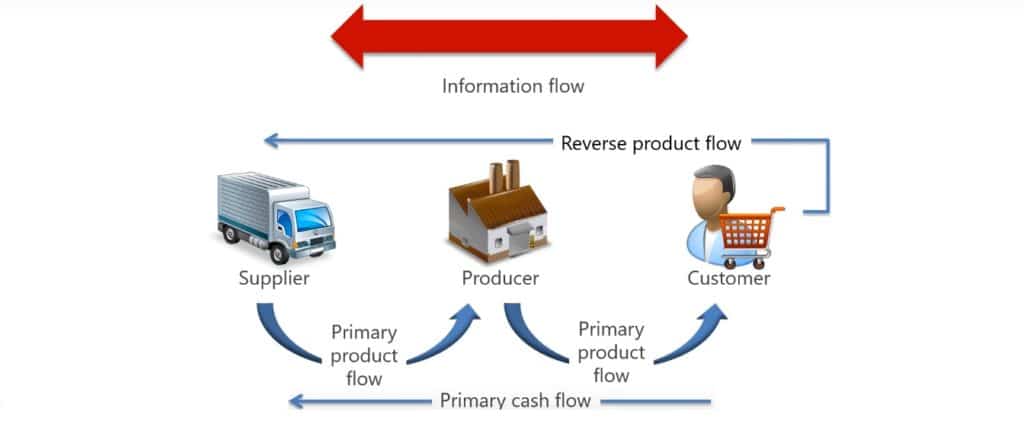

The supply chains are characterized by a set of flows, at first, we have physical flows, that is to say the move, the transport and the storage of materials and products. Products and materials are transported from production sites, then go through the hands of carriers in order to either be moved in warehouses to be stored or inside factories to be manufactured or transformed.

A real chain of actors, composed of a variety of links that communicate with each other.

Then these transformed products can be delivered to suppliers or wholesalers, who deliver them to sellers that trade to consumers in exchange of money. Lastly, the product can be returned by the user in case of dysfunction for instance.

The supply chain also integrates financial flows, cash flows that reward the different actors.

Theses flows move in the opposite way of the physical flows and include the different transactions realized by all the carriers and companies of the network.

They include the billings, the receipts and other types of payments.

Naturally, the supply chain can not work without an efficient flow of information between the different actors. These data include products catalogs, prices, the transactions history, the volumes handled, but also the suppliers’ list or any other type of database.

The treatment and analysis of the latter thanks to KPIs (Key performance indicators) is leading in a strategy of supplying and in its efficiency.

Logistic and supply chain management, what are the differences?

Two terms not to be confused with. Indeed, the logistic is an integral part of the supply chain management and is one of the branches.

Of military origin, the term “logistic” is an ancient term which by definition is described as activities of transport, travel, storage and packaging of a company or an organization.

All these activities are essential for the proper internal and external functioning of the company.

While the primary objective of the supply chain is the competitive advantage via the optimization of different processes, the logistic on the other hand has the purpose to answer the customers’ requirements.

Forecasting, pillar of the supply chain’s performance.

The worst-case scenario for a retailer: to be out of stock and not being able to answer the demand.

This is the main challenge for the supply chain professionals, to manage the stock, the demand and realize the order forecasting in order to be able to anticipate.

It is the predictive analysis of data that will allow to have efficient supply chain. Indeed, supply chains have to find the balance between client satisfaction and economic profitability, to avoid overstock, but also stock shortage.

This capacity of analysis and forecasting enables a very good understanding of its field of activity, and of the market and clients’ behaviors.

A good forecasting ensures a decrease of the costs especially when a contract of resupplying is signed with the suppliers, knowing that the price changes regarding the quantity ordered.

Tools and machines at the service of humanity: supply chain’s solutions.

The major technological advances in terms of automation and artificial intelligence, have allowed supply chain professionals to adopt IT solutions that are powerful and reachable in terms of use.

The supply chain sees further and further.

The dream of every supply chain professional would be to predict the future.

The idea of short-term, mid-term and long-term visibility seems essential on volumes that are handled to be able to satisfy the client. Trade flows and exchanges are more and more consequent and reach a rhythm that demonstrates that manual and human work alone can no longer answer the consumers’ needs.

Supply Chain actors have therefore been able to use tools and develop solutions, software and machines that are able to facilitate, reduce, or automate the daily tasks that are tedious, both physically and mentally.

Where robots and drones will perform tasks such as order picking and transit, powerful software solutions coupled with artificial intelligence and machine learning algorithms allow professionals to establish precise forecasting of the demand, and thus optimize their supply chain.

It is precisely what Vekia proposes in its solution.

Towards a more responsible supply chain.

The supply chain represents a consequent economic market, in proportional growth with the globalization of our society and the multiplication of trade flows.

Social, societal and environmental problematics are now at the heart of large companies’ strategies, the social responsibility of these companies (CSR) is frequently linked to their supply chain.

The choice of suppliers and partners, the reduction of energetic and greenhouse gas emissions’ costs, the respect of laws and work values are parts of practices put in place by the organizations.

Supply Chain solutions are there to help humans in this transition, and then share their capacities and technologies for the benefit of a better world, for humans and the planet.

How you can put your Supply Chain data to work

If you are a Procurement Manager, Sales Planner or Supply Chain Director, you are confronted daily with a strategic subject, the use of data. Due to the scale and impact of such a project, we observe many companies being held back by the legitimate fear of change.

Where to start? How to measure your data performance? Allow us to guide you through the steps so the implementation and use of data in your Supply Chain is a success!

Why use your Supply Chain data?

You already know your customers have become more volatile than ever before, and they want faster service and lower prices, with greater choice for distributors and manufacturers. To meet these requirements and to know whether you’ve done so, you have access to different data sources (both internal and external). This collected data will provide a more clear vision of your business and help you to manage it with accuracy.

By making the best use of your Supply Chain data, you’ll be able to:

Monitor your activity: This is the first level of information provided to you by quality data. The purpose is to continuously diagnose your Supply Chain and monitor the indicators that are important for your S&OP processes.

Detect anomalies: Receive alerts to outlier data points that hinder the best performance of your Supply Chain and resolve them quickly to mitigate consequences.

Improve forecasting: With a qualitative data system, you will be able to forecast your future activity with greater accuracy and certainty, and gain in responsiveness, and performance.

The prerequisites for making good use of your Supply Chain data

Have accessible data

The first condition for a good use of data is to have data. Good news, you made it! The different departments of your company already use their own data systems.

The bad news is that it is scattered throughout your organization and you’ll have to aggregate it. This is a tedious first step because nothing is standardized. Each team has its own way of structuring its data, and sometimes it varies with each person on the same team!

With regards to the new data that you do not yet have and that you are going to start collecting, make sure that you start off on the right foot and that your data meet our prerequisites below!

Provide a solid technical foundation

To support all this information, it is essential to provide a solid technical foundation. On the collection side, it is important that practices and tools are consistent throughout the organization, or that differences are known and voluntary. On the other hand, hosting must be carried out on servers and data warehouses that are sufficiently powerful and equipped with sufficient capacity. As for the data, it must be redundant (stored and updated in several places).

Not providing a sufficient technical base means limiting the capacities of your project from the outset and multiplying the risks of malfunctions. With limited storage capacity, you will need to restrict the history of your data or forget about information that might have been useful. With cheap servers, you are exposed to regular slowness or crashes that will cause information loss.

In short, before you think about collecting and using your Supply Chain data, think about providing it with a stable and powerful environment!

Evaluate your data quality

Do you have a lot of data at your disposal? That's good! Do you have the technical means to support this volume in good conditions? Great! But are they qualitative? This is the most important condition, because it is better to act with little knowledge of true information than on the basis of much false information.

Several essential criteria define quality data. It must be consistent with reality, unique (not having the same information defined in several ways), understandable, structured and documented. If your data does not meet these criteria, you can use them, but the results will not be available. Imagine your doctor prescribed a treatment with knowledge of bad symptoms- you would not get better and it could even have undesirable side effects!

Beyond a prerequisite, quality control is a continuous task to perpetuate the value of your database, which is enhanced every day with new data generated automatically or manually.

Boost your data security

Another requirement is that you must heighten your data security. You handle confidential information about you and your customers, including payment information. It is your responsibility to ensure that this information is not available to anyone.

While companies have long chosen to keep their data warm at home, the norm today is the use of the cloud. Today, cloud players allow you to put your entire database on a remote server (at Vekia, we chose Microsoft Azure). In addition to the security provided by an actor like Microsoft, this process frees you from server maintenance constraints, instability risks, and allows your data to be accessible by your various central offices around the world. In addition, the cloud offers a geo-redundancy service that allows data to be duplicated in several centres around the world to protect against technical or natural incidents.

Brace for change

The last prerequisite is not operational, but your mindset. Starting a data valuation project thinking that all you need is a budget to invest would be idyllic. Your teams' jobs will evolve, leaving behind them tasks that have become technologically obsolete (such as filling excel files on hundreds of lines) to replace them with more automation, supervision, analysis and decision-making.

These changes only happen if you are prepared for them and if you have prepared your teams for them, who will see their daily lives change.

Which data should you collect?

The basic data of your Supply Chain

As a Supply Chain expert, it is essential for you to collect certain standard indicators of your Supply Chain. At the same time, having a quality data history is a substantial plus that can accelerate the ROI of your project.

You must at least have access to article (volume, brand, price, lifespan, etc.) and supplier repositories (name, purchase conditions, types of discounts negotiated, cadencier, catalogue, etc.), information from your logistics network (warehouses, hubs, stores/agencies, etc.), your movements (sales, stocks, orders, receipts, inventories) and your customers (contracts, loyalty, etc.).

Depending on your sector, other information will be added or replaced. If you manage field services for example, you will need to have the data of your vans (location, distance travelled, maintenance costs, etc.). Beyond the basic data mentioned above, it is up to you, therefore, to find out which data is specifically relevant for your company.

The data you already have

This step is in line with the first prerequisite we mentioned. To know what data your organization already has, you will need a data project manager. Its role will be simple: it will have to be responsible for collecting and making available to employees all the organization's data.

To do this, it will create a used data inventory based on what state they are in (see the quality prerequisite), by means of a mapping of the data held by the various services for example.

Exogenous data goes further

In the introduction, we mentioned the possibility of using, internal, external or exogenous data. By observing the environment in which you operate and detecting synergies with your business, you will be able to better predict a movement in demand, or better identify opportunities that are available to you. For example, for a personal service company, an aging population in a defined area may represent an opportunity. The development of an epidemic will lead to a jump in the urgent demand, and therefore in the human or material resources to be mobilized. In the case of a textile manufacturer, we can estimate the impact that the virality of a part on social networks will have on the production and supply to be expected.

To collect this data, you can simply subscribe to services that provide you with the desired information. At the same time, INSEE data is easy to integrate and sometimes free. You will be able to implement school holidays, weather, economic or demographic data directly in your tools.

Build a quality database

Analyze problematic data sets

As we have seen, it is likely that your database is punctuated by errors. Most often, these are problems that can be classified into two categories:

Unrealistic data: You may be confronted with data that simply cannot reflect reality. A negative stock or sales higher than the mobilized stock are obvious examples of a lack of realism in the data. Information of this type clearly indicates a lack of quality and becomes unusable.

Unstructured data: In addition, your data may be accurate, but not properly linked to other data. For example, the system does not know which supplier to order a given part from. This prevents you from analyzing certain synergies in your Supply Chain and hinders the automation of certain operations (here, we will not be able to automatically replenish the part because the tool will not know where to order it).

Data analysis work will make it possible to identify errors like these.

Data cleaning

Once you have detected a problem, you will first have to locate the cause. Does the error occur when sharing the data? About his treatment? Or directly to the collection?

At Vekia, data-scientists have observed that a data problem often comes from a stage of human manipulation. In this case, you can set up precise and detailed processes that will guide the participants and limit errors.

The objective of data cleaning is to emerge with reliable data that accurately reflects reality and is as detailed as possible to avoid structural problems. Unfortunately, some errors are still difficult or even impossible to detect today because they do not seem unrealistic. We cannot be fully certain that a base is totally healthy and we are all faced with a margin of error.

Generate performance indicators

Collaborate with data experts

Beyond being able to generate KPIs, you need to be able to interpret them! This is why you will have to establish a collaboration between data experts, and Supply Chain experts (you). The Data team will provide you with KPIs but may not be able to translate them into concrete facts. Your role will be to understand what these indicators of your Supply Chain performance show.

Refresh your KPI analysis tools

You are well placed to know that the efficiency of your Supply Chain is defined by many different factors. To be able to monitor your organization's performance, you will need analysis tools that allow you to explore your data and indicators via a specially designed interface. The real added value of your data lies in the way you can visualize it and interact with it.

The more powerful the tool you use, the more you will be able to inspect your data in depth, make decisions based on proven facts, and monitor the impact of your actions.

Diagnose your Supply Chain

Pinpoint cause-and-effect relationships

That's it, the time has come... You can finally use your data! Here, your Supply Chain expert cap is your best ally. Thanks to your data work and your analysis tool, your Supply Chain has gone from an immaterial and frightening colossus to a playground that you can explore from top to bottom to discover its secrets.

You are in the front row to observe your Supply Chain, whether at the macro or micro level. Above all, you can more easily investigate the causalities in your Supply Chain system. Is the non-sale of a product due to a lack of demand? To a breakup? Is there incorrect information in your database from you or your supplier? You can explore these different paths quickly.

Recently, we were able to meet a similar case with our client Engie Home Services. By working together on the data, we detected too much stock coverage on some parts, which represented a cash flow mobilized for items that are unlikely to sell for several weeks. We were then able to work on reducing stock coverage on these references, while increasing their availability rate.

Without data analysis, we would have missed this crucial improvement in the inventory optimization process.

Conclusion

The aim of this forum was to have provided answers to your questions, and to allow you to approach your project more calmly.

With the variety of collection sources and the growth of the IOT, the data will only become more relevant and volumetric in the coming years. There is no doubt that suppliers and other Supply Chain functions will be assigned tasks previously reserved for data scientists.

Among the companies we meet that wish to integrate artificial intelligence into their Supply Chain Management, many aren’t ready from a data point of view. We are convinced that this is a turn to be taken as soon as possible to limit the delay against those who have already passed it.

Using good data correctly has become a prerequisite for the efficiency of your Supply Chain, you possess the tools to be an active part of this change and no longer simply react.

[Inside Vekia #2] Meet Cyril, Product Owner at Vekia.

Discover the people behind our solution and their expertise.

Second edition of [Inside Vekia] ! For this second part, we decided to go have a chat with Cyril Gryzon, who has been Product Owner at Vekia for almost three years now.

What do you do at Vekia? What is your area of expertise?

I am Product Owner at Vekia, working within the product team. I’m responsible for defining new features and prioritising our client’s feedbacks with the Delivery team.

So far our product is our SaaS solution, used everyday by our clients for optimising their supply chain. Another mission that I’m working on is to design the UI (User Interface) and improve our UX (User eXperience) within the product.

What would you say are the key skills you bring to the company?

So yes I would say both user experience design and product management. I love working and thinking about how we can improve our platform to the users, doing that requires to think about the UX while prioritising our backlog.

Our product is quite complex (Supply Chain, Artificial Intelligence, Machine Learning) and UX has a key role to play in terms of making it simple to our users and this is where I fit the most.

How and why did you come to work for Vekia?

I used to work in a B2C startup called Giroptic, designing 360° cameras. The experience was totally great and I’ve met a lot of talents.

After this experience, I wanted to switch from B2C from B2B and this is how I landed at Vekia. I wanted to see the difference between both universes and then decide which one I liked the most.

Furthermore, i wanted to have a product that is complex in the way it’s designed and in the way it has to be relevant to the user, and I found that with Vekia, the area of supply chain, algorithms and artificial intelligence are very complex.

Where do you see the supply chain environment in 2100?

Something ultra automated, where human action would be almost untouched, the idea, and that is something we value at Vekia is to automate as much as possible when it comes to process inside the supply chain.

As for now it is mainly focused on stock management and forecast computation, the idea is that tomorrow the algorithm will be giving out the tasks directly to robots and machines.

What is according to you the best quality for a coworker?

I would say cohesion is important, having someone who is a team player. Each of us has skills and we like the skills to complete each other. The idea being that inside the team, everything we suggest (features, user’s feedback, roadmap…) is discussed and we come to a global agreement.

That’s what we do in the product team, with other Product Owners and Developers, we each have our own way of doing something, despite that, when we launch a new feature, we know everyone agreed to it, and we move towards the same goal.

We answer the user’s needs and we know how to do it. So i would say team player, listener, but also a fun and social side, it’s always nice to have people you fit with at work. So yes, team player with a touch of fun and synergy between the personnalities and the skills.

What do you like the most about living in Lille?

First of all I grew up here, so what I like is having my friends and family close to me. Lille is a really nice city, and it’s beautiful.

The city itself is really cool and pleasant, there is an atmosphere here that I like. Lots of things to do, we are close to Belgium, the Netherlands, Paris, England, and one hour away from the sea.

Then of course there is La Braderie de Lille! (Biggest flea market in europe).

Vekia has now moved to a new office, what is the best memory you had in the former one?

I remember one day we had a mixing class session, everyone brought their own records, turntable, soundsystem, beatbox… We had a DJ masterclass by some colleagues for us.

The atmosphere was awesome but unfortunately it didn’t helped me to scratch like pro!

If you had to describe the Vekia solution in 3 words what would they be?

Optimal replenishment solution 🙂

Choose the next person that will be interviewed!

I choose Sylvain !

Blockchain : The future of the Supply Chain? Interview with Manuel Davy.

“We will be led in the following months and years to put blockchain functionalities in place in our roadmap.”

As the Bitcoin is at its height and is currently traded around 50 000 euros, the Blockchain technology, is gaining more and more grounds and its adoption is increasing in every activity sector.

Here is the definition that we can find on the following website economie.gouv.fr :

“Created in 2008, the blockchain is first a technology of storage and data transmission. This technology offers high standards of transparency and security because it works without any central review body. More specifically, blockchain allows its users – connected via a network – to share data without intermediaries.”

Internet of the future for some, illusion without regulations for others, we chose to discuss it with our CEO Manuel Davy, in order to know his view on the subject and its application in the world of Supply Chain.

What does the blockchain represent for you?

It is a disruptive technology in terms of storage and data certification. It has already begun to revolutionize the world of currency with the bitcoin, and it is beginning to bring many use-cases in industry, for example the insurance through the notion of smart contracts. I strongly believe in its development in every field of human activity that involves transactions.

Does this technology have a future in the world of Supply Chain? If it does, what benefits or innovations could it bring?

The supply chain is a tool used to make transactions of physical goods, we will inevitably find blockchain on some payment and insurance aspects. But I believe that most of the use-cases need to still be identified. I have some in mind.

First of all, I think that given the impact of actors such as Amazon, the B2C and B2B clients will become more and more demanding concerning the time of their purchase and the delivery, the reliability of the service and the choice between several products.

The consequence is direct: the stock has to get closer to the clients. But it has a cost, it will be necessary to share this cost between counterparts, even between competitors, namely to have common logistics platforms in the periphery of the large cities.

Blockchain could be used to certify the stock in a warehouse where everything is shared: two identical products, stored at the same place could belong to two competitors. The blockchain will enable to avoid conflicts between them by certifying the property of one or another piece in stock.

Another use-case is linked to the development of the circular economy. Indeed, more and more companies start to put replacement parts that are still in working order back in the circuit in order to be used for devices reparations.

Each piece has a story (number of hours of function, seniority, working order) that requires an individual traceability and some guarantees of its proper functioning. Blockchain brings a technology that allows to secure this information throughout the piece’s life cycle.

We can even consider smart contracts that automatically trigger a reimbursement or a replacement in case of technical failure during the warranty period.

Is it a technology more or less expensive than the technologies currently used?

Difficult to say given that there is no equivalent for now.

What would be for you the limits of the blockchain for the world of the Supply Chain? Is its conception compatible with the latter?

As many new technologies, the limit is in the capacity of the companies to adopt new ways of working. It will have more important success with supply chains that are in the making (new companies) or in important transformation.

Beyond this limit, the blockchain technology is perfectly adapted to the world of the Supply Chain.

Do you know Vechain’s ecosystem? What might be its impact on the supply chains over the coming years?

Vechain is a great example of blockchain application in the supply chain sector, especially the use-case on wine traceability in order to certify their authenticity and avoid counterfeiting.

I think that most of the brands subject to counterfeiting see in it a true solution to certify their own products.

This will largely develop. We can also think about it in the field of medicine, in which the certification of the product is essential, just like food products with a label or a designation of origin.

Could Vekia be led to use this technology in its solution one day?

That is part of the technologies that we follow because it has natural compatibility with the supply chain (transactions). We will be led in the following months and years to put blockchain functionalities in place in our roadmap.

Do you personally own cryptocurrency?

No, the investment in which I believe the most is Vekia.

Decision impact: 10 reasons to implement the new generation of business oriented metrics.

By Johann Robette, Supply Chain Expert @ Vekia

How to measure performance ?

Most important decisions in companies are based on some form of forecasting: decisions to hire, to develop a new product line, to expand into new territory, etc.

Therefore forecasting plays an important role in the day-to-day running of our supply chains.

THE ROLE OF THE FORECASTER IN THE ORGANISATION

Interestingly, the need to predict is so critical and requires such expertise that it has led to the creation of a dedicated profession: forecaster.

From an organisational perspective, companies have created and then specialized this expertise around dedicated functions, dedicated teams, and sometimes even entire dedicated departments.

Most of the time, these structures are supervised by Supply Chain departments.

Such organisation of the forecasting function in companies have numerous merits, in particular, to bring together the experts in this subject in teams where they can share their practices.

However, this separation of missions poses a key problem. By separating the “forecasting” function from the “decision-making” function, many companies have, in a way, created silos that lead to sub-optimal performance.

THE CONTRIBUTION OF FORECASTING TO BUSINESS PERFORMANCE IS COMPLEX TO MEASURE

And here’s why: although the forecast plays a key role in the decision-making process, it’s not the only one.

Other elements also have to be considered, often in the form of constraints and other business rules.

As a result, it is often complex to measure precisely the contribution of the forecast to the final outcome, i.e. the performance of the decision taken.

For example, when deciding to purchase goods from a supplier, the demand forecast is obviously really important, but so does the allowed pack-sizes, the minimum order quantity, the storage finite capacity, etc.

Everyone is aware of the high value of forecasting, but its real business impact is often difficult – if not impossible – to measure.

THE CHALLENGE IS TO FOCUS ON THE RIGHT FORECAST METRICS

Of course, all forecasters regularly evaluate the reliability of their forecasts, and many formulas exist for this purpose. These metrics focus on the intrinsic quality of the forecast produced and are generally called “Forecast Accuracy” metrics.

Doing so, they often leave out the analysis of final forecast-based decisions and their relevance to the business.

At Vekia, we’ve been making this observation for quite some time. And for sure, we are not the first nor the last ones to identify this important limit.

As we love taking up challenges, we naturally asked ourselves: how can we evaluate the quality of a forecast so that the decisions it leads to are the best ones? In other words, what makes a good forecast ?

What makes a good forecast ?

To understand what a good forecast is, it is necessary to go back to the purpose of forecasting.

In a recent talk at Lancaster’s CMAF (Centre for Marketing Analytics and Forecasting), Paul Goodwin reminded us that forecasts are not an end but “are done to support decision-makers so they can make better decisions”.

FUNDAMENTALS OF FORECASTING

Let us briefly recall the state of the art and the fundamentals of forecasting.

The following definition of what an ideal forecast is is widely shared. An ideal forecast is a perfectly true prediction.

For example: “If 996 units sold were forecasted and, at the end of the day, 996 units were effectively sold, then this forecast was perfect!”

However, it is obvious that despite all efforts, the future is never known with such certainty. Therefore, to measure the quality of a forecast, the practice is to measure its error. For example: “If 996 units sold were forecasted and, at the end of the day, only 900 units were effectively sold, then this forecast made an error of 96 units”

The main mission of forecasters is to generate forecasts that minimise this error. This error measurement is made possible by a dozen different “Forecast Accuracy” metrics to which are added countless variants developed by companies for their specific needs.

THE BEST FORECAST IS THE ONE THAT ALLOWS YOU TO MAKE THE BEST DECISIONS

Unfortunately, this approach, reinforced by decades of practice, leaves out an essential point: the purpose of forecasting is not and has never been to provide the best forecast ever! Its purpose is to provide the best forecast for a given specific use.

The best forecast is therefore not the perfect one, but the one that allows the best decisions to be taken. The mission of forecasters should therefore not be to minimise the error between a forecast and the reality but to minimise the decisions errors.

Here’s an example. Let’s imagine a very simple decision process, taken from everyday life: every evening, a woman consults the weather forecast to decide whether or not to take her umbrella the next day.

If we focus on the forecast error, then when the forecast does not predict rain and indeed it does not rain the next day, the forecast was perfect. But, on the other hand, if the forecast calls for 10mm of rain and it turns out to be ten times more, then the forecast was wrong with a significant error.

What is being measured here is the intrinsic forecast error.

But let’s focus now on the decision made. In the specific context of the “to umbrella or not to umbrella” decision, the above error wouldn’t have had any impact on the decision taken. In both cases, the woman would have made the right choice and taken her umbrella. In terms of its use, the forecast was therefore perfect.

Thus, the quality of a forecast totally depends on its use and the decisions it trigger.

Yet, as we have seen, forecasters only have metrics that measure the intrinsic accuracy of the forecast. None of them takes into account its actual use.

This does not mean that these metrics are of no interest, far from it. But we must recognise that they are not the most appropriate ones from a business perspective…

Towards a new generation of “decision impact” metrics

Fortunately, it is quite possible to approach the quality of a forecast differently. To do so, a new generation of metrics must be introduced. Those metrics are called “Decision Impact” (and noted “DI”) and no longer focus on intrinsic error but rather on the quality of the decisions made.

BUILDING A DIGITAL TWIN

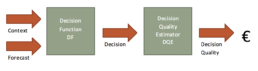

The proposed metrics requires the creation of a computer model (or “digital twin“) that can, for any forecast input, simulate the decision process and evaluate the quality of the final decision.

It is then necessary to model the decision process (through a Decision Function denoted “DF”) and to define a measure of the decision quality (via a Decision Quality Estimator denoted “DQE”).

The quality of a decision can be expressed in many ways. However, we highly recommend expressing it as a financial cost as this allows multiples use cases that will be discussed later on.

Of course, the perfect modelling of processes and impacts will sometimes be difficult, if not impossible, to achieve. But a simplified model often manages to effectively “approximate” much more complex realities.

LEVERAGING 3 TYPES OF FORECASTS

Three different forecasts are needed to generate the proposed new metrics and to demonstrate their value:

· The so-called “actual” forecast, resulting from the forecasting process in place.

· The so-called “naïve” forecast, resulting from the simplest forecasting method that would naturally be used if the forecasting function did not exist in the company.

· The so-called “oracle” forecast, i.e. the ground truth, measured a posteriori and corresponding to the observations themselves.

These 3 types of forecasts are then consumed by the Digital Twin to simulate the related decisions and their respective quality referred to as a “Decision Impact”.

· The cost of the decisions enabled by the actual forecast is denoted “DIa”, ie. Decision Impact of index “a” for “actual”. It measures the quality of the decision that the current forecasting process generates.

· The cost of the decisions enabled by the naïve forecast is denoted “DIn”, ie. Decision Impact of index “n” for “naïve”. It measures the quality of the decision that the simplest forecasting process would generate.

· The cost of the decisions enabled by the oracle forecast is denoted “DIo”, ie. Decision Impact of index “o” for “oracle”. It measures the quality of the decision that perfect knowledge of the future would generate.

DIa, DIn and DIo deliver valuable data about the forecasting context. But more than that, they’re the fundamental building blocks that could then be assembled to generate three insightful metrics.

The first metric denoted “DIn-o” is the difference between “DIn” (cost of the “naive” forecast-based decision) and “DIo” (cost of the “oracle” forecast-based decisions). This metric defines the complete playing field, addressable through forecast improvement.

DIn-o= DIn – DIo

The second metric denoted “DIn-a” is the difference between “DIn” (cost of the “naive” forecast-based decisions) and “DIa” (cost of the “actual” forecast-based decisions). Therefore, it measures the added value delivered by the actual forecasting process.

This metric relates to the notion of FVA (Forecast Value Added) and enhances it by delivering a dollarized vision of the added value.

DIn-a = DIn – DIa

The last metric denoted “DIa-o” is the difference between “DIa” (cost of the “actual” forecast-based decisions) and “DIo” (cost of the “oracle” forecast-based decisions).

Therefore, it measures the maximum value that could still be delivered by improving the actual forecast process.

DIa-o = DIa – DIo

Combined, these metrics can be rendered, analysed and interpreted through easily graphical representations such as stacked bars/areas or gauges.

10 new exciting perspectives

This new bunch of “Decision Impact” metrics opens up completely new perspectives, as shown by the following use cases.

METRICS BENEFITING THE FORECASTERS

Forecasters are the very first to benefit from these metrics. Among other things, the new insights enable:

1) to have non-ambiguous “North Star” metrics that at last deliver a reliable view on the forecast quality. Indeed, it’s important to remind that traditional Forecast Accuracy metrics regularly contradict each other;

2) to select and configure correctly the forecasting models that best support the decision-making;

3) to generate a value map to clearly identify value pools;

4) to know precisely when to stop improving a forecast, as the yet-to-be-harvested added value does not worth it;

5) conversely, to know on which perimeter would benefit the most from an improved forecast;

6) to prioritize the most impactful sub-perimeter, if the yet-to-be-improved perimeter is too large given the available resources;

7) to evaluate a dollarized FVA for each contributor/step of the forecasting process.

METRICS BENEFITING THE WHOLE COMPANY

The benefits of these new metrics are not limited to the forecasters only. The new insights enable the whole company:

1) to streamline and smooth the communication between departments about forecasts thanks to metrics that are, at last, easily understandable for each stakeholder;

2) to evaluate and share the delivered value of the forecasting process (and of its subparts: per forecaster or per step) in a fair, non-contradictory and easy to understand way.

As these metrics are more than pure forecasting metrics, the same approach could be applied to measure the impact of changing input constraints instead of changing input forecasts.

For example, this allows the evaluation of the pack-size costs or the impact of the delivery frequencies… It’s then a great tool to point out desirable areas for improvement, etc.

Conclusion

Each and every company is engaged in a daily struggle against inefficiencies and wastes. Silos have long been pointed out as such, and are perceived as they truly are: fractures within organisations.

The forecasting function, on the other hand, naturally shouldn’t be such as a silo, as it has a central position within the company. It is indeed a key partner for many departments and is at the very heart of key business processes such as IBF and S&OP.

However, within the practices of forecasters, performance measurement remains historically and surprisingly uncorrelated with the uses and business impacts of the forecasts.

BRINGING BUSINESS BACK INTO FORECAST PRACTICES

The hereby introduced “Decision Impact” family of metrics makes it possible to bring back the “business” dimension into the very heart of planning. The benefit being the realignment of the entire company around the business.

More than that, these metrics open up new perspectives and allow for completely new use cases around automation, prioritisation and improvement of key business processes.

“DECISION IMPACT” IS AT THE HEART OF VEKIA’ STRATEGY

These “Decision Impact” metrics have been used for several months at Vekia in the numerous contexts of our customers (retail, maintenance, energy, telecommunications, pharmaceuticals, etc.).

This demonstrated a significant contribution to decisions improvement, as they were first used 1) to select the most appropriate forecast algorithms and 2) to fine-tune our probabilistic replenishment engine to maximize the generated value.

What about your company ? Do the applied metrics aim for “perfect accuracy” or “perfect decision”? What prospects do these new metrics open up for you?

In our next articles, we will go into more detail on the operational uses of “Decision Impact” metrics.

[Inside Vekia #1] Meet Dr. Rabin Kumar SAHU, Supply Chain expert and researcher.

Discover the people behind our solution and their expertise.

For our first episode of [Inside Vekia], we chose to kick things off with our beloved Dr. Rabin Kumar Sahu, supply chain expert and researcher at Vekia!

After successfully graduating from a master’s degree in supply chain and operations at Ecole Centrale de Lille (France) and the National Institute of Industrial Engineering (NITIE) in Mumbai (India), Rabin carried out his Mechanical Engineering from the Veer Surendra Sai University of Technology in Burla (India).

Rabin develops data-driven methods to manage supply chains optimally. After managing industrial operations, he focused on analytical planning and how organizations can go digital.

He has published six research papers on stochastic replenishment planning, supplier selection, promotional ordering, and performance evaluation.

What do you do at Vekia ? What is your area of expertise ?

I am an operations research scientist and supply chain expert at Vekia. My areas of expertise are supply chain management, inventory management and optimization. I currently lead the supply side solution development in supply chain planning, which primarily includes Inventory optimization, Replenishment Planning, Predictive Shipment, S&OP, Emergency Planning, etc.

What would you say are the key skills you bring to Vekia ?

I would say the skills and the expertise I bring to Vekia are first of all Mathematical optimization, that includes Metaheuristic, Combinatorial and Stochastic Optimization. Then there is

Supply chain management and Inventory control, thanks to KPIs selection and monitoring. Artificial Intelligence and machine learning, but also software skills in languages such as R, Python, Spark, Scala and Azure.

Where do you see the supplychain environment in 2100 ?

In 2100, I see a completely digital and autonomous supply chain management. I expect newer modes of transport, particularly cheaper and faster. I see decisions to be made independent of the user completely automatically. I also see continuous stream of data flow and decision making.

The converging fields of Artificial intelligence and Operations research have shown an exceptional potential to improve the efficacy of supply chains. Not only do they help reduce costs, but they also automate operations without any bias.

What is according to you the best quality for a coworker ?

I think the best quality for a coworker is to have someone who always supports the team and makes the workplace conducive.

What’s the thing that fascinates you the most when it comes to supply chains ?

The most fascinating thing about supply chains is the speed at which they change.

What is it like to work thousands of miles away from your company ?

Initially it was a bit difficult. But we kept true to our schedules and everything worked well.

When you come to Lille, what is it that you like the most ? Is there something that you always do ?

Weekly Blast #75 : Supply Chain Automation.

How to achieve the automation goals of your company ?

For this week’s blast, our team of experts chose to focus on automation, a big part of what we do here at Vekia, an important part of supply chain management.

Supply Chain Automation has been a growing trend for several years, and supply professionals in the field are investing more and more in technologies like Internet of Things (IoT), Artificial Intelligence (AI), Blockchain, Machine Learning and so on.

In 2019, 23% of warehouse managers already acquired new automation technology [1], and 50% of large global companies planned to use AI [2], advanced analytics and IoT in supply chains by 2018.

However, business-process automation is not an easy shift, and there are some factors that can help achieve the automation goal of the companies.

Here a three tips from our experts you can apply when it comes to the automation of your supply chain :

1. Make Automation a strategic priority.

Align the automation strategy with the overall business strategy of the company and make it a priority in the strategic planning process.

2. Focus on people as much as on technology.

Adopt a Human-in-the-loop strategy. This implies employee training, involvement of communication function while implementing an automation process, capability building, etc.

3. Setting tangible objectives.

Identify the processes are relevant to automate and establish key performance indicators to track the impact of automation effort.

Field Services Procurement: Six Common Mistakes to Avoid

It’s obvious that a good supply of field services is key for company sustainability in this sector. As you know, the different measures your company uses to identify the order quantity and when to order it, have a major impact on its profitability and performance. These measures make it possible to achieve an ideal balance between optimal customer response capacity and low logistics costs.

Yet, even if companies know to do everything possible to prevent their stocks from harming them, we note that many unintentional mistakes are made in this area.

What are the consequences of poor stock management? Which common supply mistakes can be avoided? What are the solutions and practices that best optimize supply management? Today, we’ll help you identify and avoid common mistakes in the procurement of field services!

Customer Satisfaction: the Primary Mission in Field Services

As always, your main objective should remain customer satisfaction. It’s time to take concrete steps to manage the situation:

- Set up a client appointment as soon as possible. As soon as you are aware of the client’s issue, your company should intervene as soon as possible. Your responsiveness makes the customer feel valued and heard, an excellent way for you to maintain customer relations!

- Resolve the issue in the same appointment. Are you forcing the customer to be free several times to fix their problem? This is a scenario to be avoided at all costs! This may additionally affect the customer experience and degrade your company's image.

The Consequences of an Incorrect Stock Level

Out of stock

As an immediate consequence of insufficient stock, the shortage causes a serious disruption in the internal supply chain.

In the best case scenario, the part you need is available in another nearby store. You’re able to quickly react, but this is at the cost of an unexpected, yet necessary trip. There is additional cost and a potential delay for the planned activities for the day.

In other cases, the business must order the part. This causes not only client frustration because the problem isn’t instantaneously resolved, but the client must also be available for a later appointment (to pick-up or receive installation). In addition to the delay, there may be additional cost as the urgent order was placed outside the initial replenishment plan. As it is an isolated incident, the usual discounts normally available are not applicable.

Overstock

Does overstocking seem like a better problem to have? Having too much stock exposes your company to another list of inconveniences and frustrations.

First, each product stored reduces your company's cash flow. This capital lockup means a loss of opportunity for your company, which could have been invested in projects with higher profitability!

Another undesirable effect is less storage area because a large quantity of unused products requires your storage space. There may be additional costs to you if this requires you to rent or build more storage space.

Finally, your stock has the potential to be saturated with low turnover references. This excessive stock can force your company to sell at a discount or even at a loss in order to limit storage costs.

Incorrect Stock Distribution

When your suppliers or production don’t enable you to have enough volume to cover your network, you’ll need to choose which logistics points to supply or not supply. This situation exposes you to another risk of poor stock allocation.

A reference in the wrong place is a problem that should not to be underestimated. The depot or warehouse supplied has unnecessary stock, and the one who needs it doesn’t have it. It is a scenario of both rupture and overstock with the aforementioned consequences. This at least doubles transport costs because once something is in the wrong place, it must be expedited to the location in need of the reference.

Poor stock allocation is a costly challenge that you must do everything possible to avoid.

Common Errors in the Procurement of Field Services

Unclear Communication Between Supply Chain Players

The team in the field is aware of their needs but don’t communicate them to the plant. The result is employees having a flawed perception of the field. To facilitate improved communication, several means can be put to use.

On the supply side, it is best practice to regularly organize field visits to be in tune with reality. You may find that you’re receiving little to no correct information from employees or methods of communication.

On your side, you can establish solutions that promote and simplify this communication channels between the different levels and players in the Supply Chain.

Untidy Supply Chain Data

You have data but your data lacks quality or volume. To act correctly, it is necessary to be able to rely on true and exhaustive information.

We explain everything in our previous forum: Our advice to better use the data in your Supply Chain

Lacking Procurement Performance Indicators

If your activity is insufficiently monitored and your performance remains unmeasured, you will find it hard to identify your strengths and weaknesses. In the Cartesian world of the Supply Chain, it is essential to rely on real indicators, rather than base performance on individual feelings and instincts.

The data you supply will allow you to establish KPIs revealing your Supply Chain effectiveness. Here are several examples for field services:

- "Review Rate": Know the ratio of clients who have had their issues resolved during the first intervention. Our client Engie, measures their "Review Rate”.

- Availability: In the most general case, availability measures when the part is available at the time it is needed. In the case of device maintenance, availability can also refer to how much time the device is operational and available, as opposed to downtime.

- Transportation Costs: Your activity in field service exposes you to transportation costs that you need to track. Optimal inventory management will reduce your transportation costs. On the other hand, if your transport costs are high or increasing, there are surely improvements to be made in your logistics.

In summary, your Supply Chain is full of information and it is up to you to reveal!

An Imperfect or Hidden Need Forecast

Many organizations lacking anticipated quantities remain. Manual replenishment occurring only when the stock is low could be valid only if certain of the constant need, but this is rare. This leaves us exposed to both shortages and overstocks because sales can weaken after a single replenishment, or perhaps accelerate before it’s been anticipated.

To best respond to an increased demand or to avoid carrying unnecessary parts, address your forecasts!

Inadequate Territorial Stock Distribution

As previously mentioned, a mismanaged distribution of limited stock is to be avoided at all costs because it leads to both overstocks and shortages. Your objective is to mobilize as little stock as possible, but not just anywhere, that's the difficulty!

Alongside this distribution concern, manual management should also be avoided. Some store locations may be tempted to overstock to avoid a break. This will result in under-stocking at other locations that can no longer meet the needs of customers. By default, that leaves us in a situation where the first who come, are the first served.

Your objective is to rationalize this replenishment. Again, based on more detailed and accurate forecasts, you’ll avoid misallocated stock.

Failure to Consider Customer Feedback

Is your company meeting customer expectations? Ensure this is the case! Clients may have had a different experience than what was intended. A lack of listening to their complaints and feedback can deprive you of vital information!

To achieve this, set up opportunities for them to express themselves after each intervention by using satisfaction forms, questionnaires, surveys, etc. Above all else, analyse their responses to identify the most frequent points of satisfaction and dissatisfaction. A lot of data is still collected without being used!

Future Improvement Opportunities

Let’s look into the future. Information technologies are constantly evolving! They will soon provide Supply Chain managers with new tools that offer ever greater agility and performance to the Supply Chain.

First, predictive technologies. They provide more accuracy and reliability to better anticipate the need. Based on advanced algorithms, these technologies transform your data in anticipation, and can even take into account external data (demographics, school holidays, weather, etc.). With reliable data and quality technology, supply can already be automated. This trend will accelerate in the coming years, as well as the autonomy of the Supply Chain.

A second opportunity to be considered is the democratization of the Internet of Things (IoT). More and more connected objects can communicate in real time about their status. This is a great help in anticipating anomalies or analysing the use of a product by the market, while also providing more services to the customer through an application for example.

We invite you to read the report of our trip to the Gartner Supply Chain Executive Conference in Phoenix, which brings together the Supply Chain trends that will mark the coming years: What I have learned from my trip to the Gartner Supply Chain Executive Conference in Phoenix (french)

Conclusion

Gut instinct feeds manual management, showing that supply is often subject to traditional methods. There is a substantial contrast between the methods used by suppliers and the solutions available to them. However, an approximate management of supply leads to lost time, extra costs and immobilization of cash. This leaves the stakes particularly high for your company.

Strong communication between the various Supply Chain players, quality data and relevant KPIs, anticipation of needs, good stock distribution and customer feedback are all key elements to optimal supply, a real guarantee of efficiency for your company!

More than just a matter of Supply Chain, a good supply will have a strong impact throughout the entire company. This will stem from the support of higher daily customer satisfaction and data-based marketing that can correctly re-set your company's positioning. There is no time to waste!

Inventory management - what more can be done with artificial intelligence

The labour market is currently experiencing transformation and is being shaken by the gradual introduction of latest innovations in tech. Artificial Intelligence (AI), specifically, has revolutionized certain fields, leading to the automation of thousands of jobs. It has also renewed a large number of professions with newly evolved and reinvented missions.

Supply-related professions aren’t immune by the emergence of new technology and are at the forefront of those constantly seeking an innovative supply chain. Among them, roles such as stock managers, suppliers or demand planners, whose main objective optimal stock management, i.e. controlling the right stock in the right place at the right time, are essentially becoming a real-time collaboration between man and machine.

For these profiles, the major challenge is to find a balance, making it possible to optimize inventory allocation and generating the lowest cost and highest margin. To address this, AI introduced in supply chain software creates a combination of efficiency and tools for a successful inventory management.

The companies who have already entered this technological sphere, have begun to move towards leading educational change to facilitate synergies between man and machine. This is a collaboration that will undoubtedly redefine daily business operations, and the scope of the stock manager in five ways.

The merging of human qualities and the machine

AI facilitates the stock manager's missions by reducing their recurring operational tasks. As an example, the automation of orders from suppliers allows him to devote more time to the analysis of high importance items and critical situations, such as quality issues and supplier deadlines.

Without AI, ordering is a technical and daily action performed by the supplier, resulting from a logical combination. Today, advances in AI simplify the supplier’s task because the only real issues in the ordering process are between the recommendation made by the algorithm and the confirmation of the business.

Rethinking supervision and control

The spectacular discoveries related to AI indicate that the stock manager will continue to be reinvented with the rise of software programs. Today we have reached a point where the volume of data generated daily is far greater than procurement teams and relevant spreadsheets. This is why AI is used as a genuine recommendation and decision-making tool.

As a true supplier/IA duo, AI anticipates problematic situations (based on the calculation of its algorithms), alerts the user and recommends the necessary controls to correct deviations, challenging his vision. The stock manager, for his part, enriches the tool with various exogenous data (local events, for example), making it possible to refine the AI calculations, and supervise consistency with the company strategy.

Identification and pursuit of the best strategy

AI is involved in this collaboration as a forecaster with all the necessary information to define the future. It allows demand planners to design different stock allocation scenarios based on different combinations of settings and constraints (Minimum quantity, Franco, PCB, supply frequency, etc.). Procurement teams will submit them to the AI to make informed decisions to determine the best procurement plan adapted to the brand strategy (sales, commercial operations, peak traffic, etc.).

Understanding, explaining, acting... Analysis at the heart of everyday life

In a context where man collaborates in this way with Artificial Intelligence, it is necessary for demand planners to include certain key information. Their objective is to monitor and orchestrate inventory management through an adequate understanding of how it works, in order to fall in line with company strategy.

That is why it is now possible, for example in the case of calculating sales forecasts, to understand product characteristics, stores, time, social networks, and the weight each characteristic caries in the demand forecast. This allows the planners to enter the origin of the result and to be able to explain it.

This process reinforces the contribution of the procurement teams' business expertise in providing new exogenous data that they believe could increase relevant and reliable sales forecasts.

A new challenge: aligning the different company visions

Procurement services are generally at the heart of the company. This confronts stock managers with varying company visions and they are tasked with crafting the most optimal solution that meets all objectives, which is a daily challenge!

Between the purchasing department that constantly drives the implementation of its new products, the network department, which constantly requires more stock for the customers and the financial department who is constantly seeking higher margins and lower costs, stock managers must manage and meet these visions. This is quite the art!

The difficulty decreases when AI comes into play, supply chain software has become a collaborative tool, saving time and providing great flexibility to manage fast and frequent changes. They become a legitimate basis for establishing harmony between services and providing optimal vision.

But for this dual provisioner/IA device to work perfectly with the common goal of finding the best balance, supply chain software must meet essential prerequisites. Supply chain publishers must use their creativity to offer work tools that pose the main advantages of being easy to use and accessibility to the largest data sets.

To date, AI has transformed the role of man to position him to the new posture of "augmented man". What will happen in the next ten years? What does AI research have in store for us? Will they have an impact how companies function today? Will we move towards a hyperspecialisation of companies by function and rather by purpose, leading to the emergence of new professional roles?

By Emmanuelle Gantier, Product Manager at Vekia